What Is Design-Build Construction?

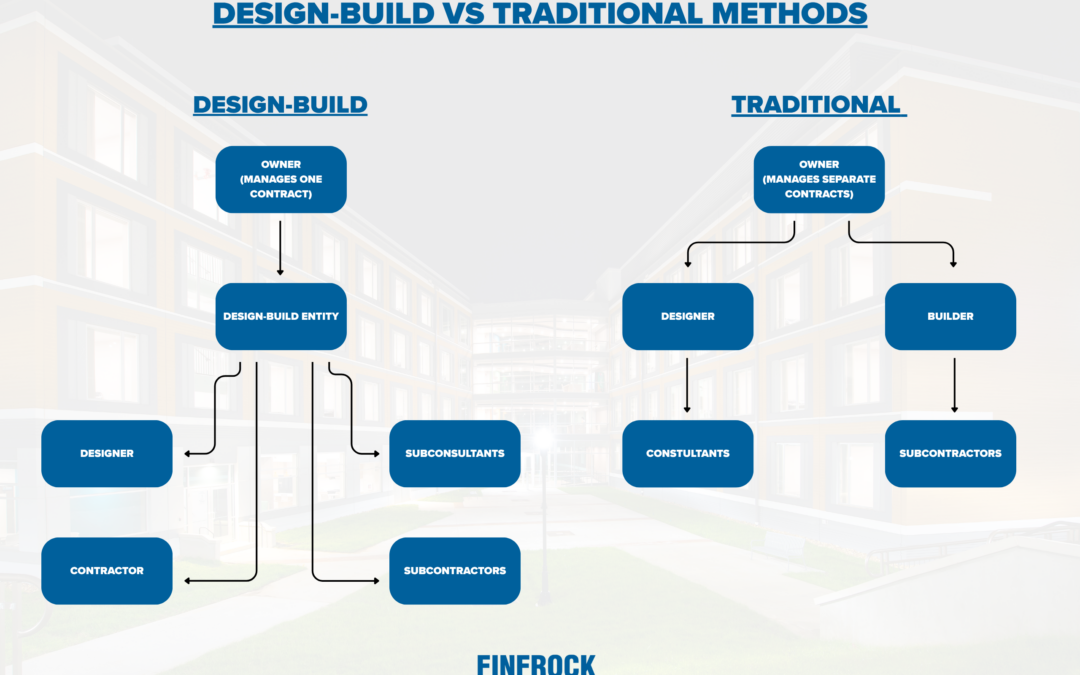

Design-build is a project delivery method in which a single entity is responsible for both the design and construction of a facility, under one unified contract. This approach replaces the traditional separation between architect and builder, creating a streamlined process led by a single source of accountability.

Common in both public and private development, design-build is increasingly favored for projects where speed, cost certainty, and reduced risk are critical to success.

In this guide, you’ll learn:

- The full design-build construction process, from site selection to project handover

- The key roles involved: owners, architects, engineers, manufacturers, contractors, and subs

- How design-build compares to other delivery methods like CMAR and Design-Bid-Build

- A full list of benefits (and limitations) for developers

- What to include in a design-build contract

- How to evaluate and select the right design-build partner

- How FINFROCK’s integrated design, manufacturing, and construction model takes design-build even further

Whether you’re exploring alternative delivery methods or evaluating project execution models, this guide serves as a deep, technical reference for developers and industry professionals who want to build smarter, with greater speed, cost control, and accountability.

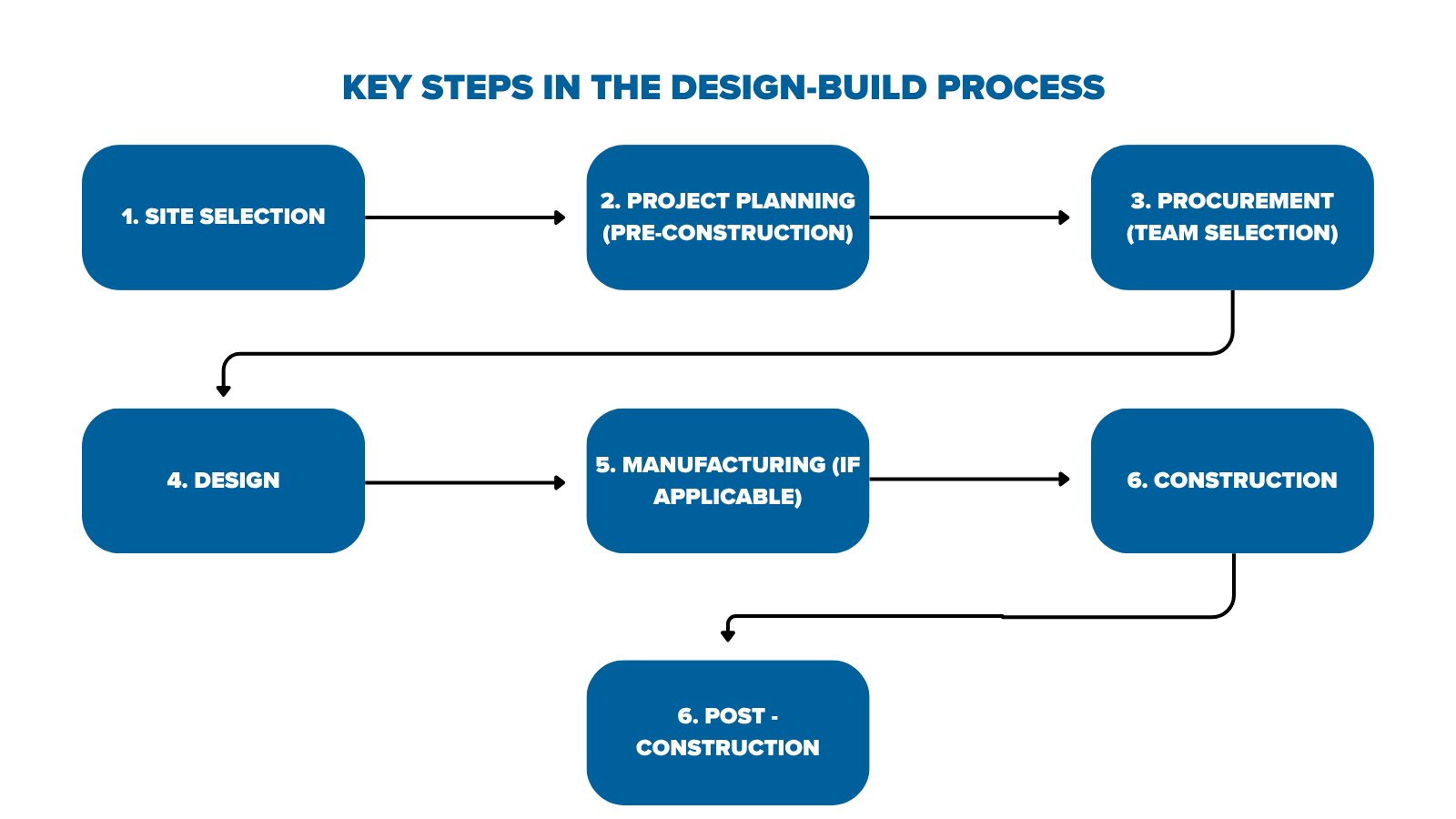

Key Steps in the Design-Build Process

Unlike traditional models with isolated phases, design-build operates as an integrated, continuous workflow. Each phase is shaped by shared responsibility for constructability, cost, and schedule—delivered by one unified team.

1. Site Selection

Early design-build involvement in site selection helps identify cost drivers, entitlement risks, and constructability constraints. The team evaluates factors like soil, topography, utilities, zoning, and environmental conditions. Early contact with municipalities and permitting authorities allows developers to align acquisition decisions with realistic timelines and reduce entitlement risks.

2. Project Planning (Pre-construction)

This phase aligns design intent with budget, schedule, and logistics. Activities include:

- Defining project vision and performance goals

- Conducting feasibility and geotechnical studies

- Starting preliminary design with constructability input

- Establishing a baseline schedule

- Modeling early costs for budget alignment

- Identifying risks and value engineering opportunities

By integrating all stakeholders early, the team reduces redesigns, accelerates permitting, and sets up reliable execution.

3. Procurement (Team Selection)

Developers use a qualifications-based selection process:

- RFQ screens firms on experience, safety, and capability

- RFP invites detailed proposals with concepts and pricing

- Interviews assess team chemistry and alignment

- Best-value selection emphasizes past performance and delivery strategy

The result is a single accountable partner with the capacity to deliver across design and construction.

4. Design

Design progresses through coordinated stages with real-time input from construction and estimating teams:

- Concept and schematic design define goals and layouts

- Design development refines systems and materials

- Integrated reviews ensure budget and constructability alignment

- Phased permitting can enable early site work

- Construction documents are tailored for procurement and, if applicable, manufacturing

This iterative process reduces rework and supports faster, more efficient approvals.

5. Manufacturing (If Applicable)

Manufacturing applies when precast or modular systems are used. Key benefits include:

- Shortened timelines via parallel off-site fabrication

- Improved quality through controlled production

- Synchronized delivery and installation

- Reduced on-site labor and safety risks

Design-build firms that manufacture in-house ensure fabrication is fully aligned with design and construction requirements.

6. Construction

With upstream coordination complete, construction proceeds efficiently.

- Site mobilization and foundational work are ready to go

- Structural systems arrive pre-fabricated or pre-ordered

- Real-time coordination resolves field issues quickly

- The team adjusts sequencing as needed without delays

- Quality and safety protocols are enforced by the same team from pre-con to build

This approach reduces RFIs, change orders, and handoffs, improving timeline predictability and budget control.

7. Post-Construction

Handover is seamless due to continuity:

- Punch lists are shorter thanks to proactive QA/QC

- Systems are tested and commissioned with team familiarity

- Closeout packages are complete and accurate

- Facility staff are trained with direct access to project experts

- Warranty service is streamlined through the same point of contact

The developer receives a building ready for immediate use—with confidence in long-term performance.

Who Is Involved in Design-Build

A defining feature of design-build is the unification of roles that are traditionally divided across separate firms. Instead of fragmented responsibilities and contractual silos, the design-build model brings all key players under one contractual umbrella, fostering collaboration, accountability, and efficiency throughout the project lifecycle.

Below are the primary parties involved in a design-build project and how their responsibilities align within this integrated model:

- Owner / Developer

The owner defines the project goals, approves the program, budget, and schedule, and works closely with the design-build team throughout. While the owner remains actively engaged, their day-to-day burden is reduced by having a single point of contact and streamlined communication channels. - Design-Builder (Lead Entity)

This is the firm or team responsible for delivering the project under a single contract. The design-builder manages both design and construction, often assembling an internal or external team of architects, engineers, and trade partners to execute the work. - Architects

Architects in a design-build setting work as part of the unified delivery team, rather than independently contracted by the owner. They collaborate early and continuously with engineers, construction managers, and estimators to ensure the design aligns with budget, schedule, and construction feasibility. - Engineers

Structural, civil, MEP, and specialty engineers contribute to early design development and stay actively involved throughout the project. Their early collaboration with construction teams helps optimize systems for constructability and long-term performance. - General Contractor / Construction Management Team

This group manages field operations, site logistics, subcontractor coordination, and safety oversight. Unlike in traditional models, the construction team is engaged from the start, contributing to design reviews and preconstruction planning. - Manufacturer / Fabricator (if applicable)

For projects that include prefabricated or precast elements, the manufacturing team works alongside designers and builders to develop production plans that align with structural design and construction sequencing. Their involvement early in the design process ensures fabrication drawings are coordinated with installation requirements. - Subcontractors and Subconsultants

Specialty trades, consultants, and suppliers are often brought in earlier than in traditional delivery models. Their early input helps resolve constructability challenges and supports better coordination during execution.

In a well-structured design-build team, these roles are not siloed. They operate in a continuous feedback loop, with shared objectives and a unified commitment to project success. This structure enables earlier decision-making, fewer scope gaps, and more predictable outcomes for the owner.

Design-Build Myths and Misconceptions

Despite its growing popularity, design-build is still widely misunderstood. Many developers and stakeholders approach the model with outdated assumptions based on experiences with traditional delivery methods. Below are some of the most common misconceptions—and the facts that clarify how design-build actually works in practice.

| Myth | Reality |

| Design-build eliminates competition and drives up cost | Competitive bidding still occurs, but at the vendor and trade level. Owners benefit from cost control through early estimating, value engineering, and open-book pricing. |

| Design-build locks the owner into decisions too early | While early decisions are encouraged, the model allows for flexibility through phased design and integrated cost modeling. Owners have opportunities to adjust scope and systems along the way. |

| Design-build limits owner involvement | Owners remain central to the process, often more engaged than in traditional models. The difference is that they communicate with a single team rather than multiple, disconnected entities. |

| There’s a conflict of interest between design and construction | With a unified team, priorities are aligned around project success, not competing contracts. Trade-offs between design, cost, and constructability are resolved internally, with the owner’s goals at the center. |

| Design-build reduces design quality or creativity | Integrated collaboration actually supports more informed and buildable design. Architects work closely with engineers and builders, resulting in higher-functioning, better-coordinated projects. |

| Legal recourse is more limited | Owners still retain contractual protections. In fact, having one entity accountable for the full project often reduces disputes and eliminates gaps between designer and builder liability. |

These myths often arise from a lack of exposure to well-executed design-build projects. When the model is implemented with clear communication, qualified teams, and early collaboration, it consistently delivers high-performing buildings with fewer surprises and greater value.

Real-World Results: Design-Build in Action

The benefits of design-build aren’t just theoretical—they’re measurable. One of the clearest examples is the Endless Summer Resort, where FINFROCK delivered Universal Orlando’s largest hotel in record time. By serving as architect, structural engineer, manufacturer, and contractor under one contract, FINFROCK streamlined every phase of the project—from entitlement through occupancy.

The Surfside Hotel opened just 15 months after groundbreaking, marking Universal’s fastest and most efficient hospitality build to date. That speed was possible because of early collaboration, a fully integrated team, and the use of our DualDeck® Building System to reduce on-site labor and accelerate structural installation.

The project also included a 5-level parking garage, critical vertical cores, and the site’s central utility infrastructure—all coordinated and delivered as part of the design-build scope. With over 2,800 rooms across Surfside and Dockside, Endless Summer showcases how a vertically integrated model can deliver large-scale results with speed, control, and confidence.

Endless Summer Resort Hotel Design-Build Project by FINFROCK

The Owner’s Experience in Design-Build

One of the most important distinctions in design-build is how it transforms the experience of the owner. Rather than managing separate contracts and intermediaries, the owner interacts with a single, accountable team that carries responsibility from concept through completion. This structural change creates a more streamlined, collaborative experience—one that minimizes administrative burden while increasing visibility and control.

Here’s what developers and owners can typically expect throughout a design-build project:

Early Engagement, Clear Expectations

From the outset, the owner is involved in setting project goals, priorities, and constraints. The design-build team translates these objectives into design concepts, construction strategies, and preliminary budgets—often far earlier than in other delivery models. Early participation empowers the owner to make informed decisions that influence cost, functionality, and schedule.

One Point of Contact for All Decisions

Instead of managing separate relationships with architects, engineers, and contractors, the owner works directly with a single team lead or project executive. This consolidated communication structure reduces confusion, accelerates issue resolution, and ensures accountability remains clear throughout the process.

Active Input Without Daily Oversight

Owners remain involved in milestone decisions, approvals, and design reviews, but are not required to manage day-to-day coordination across disciplines. This balance allows developers to focus on high-level project direction while trusting that the integrated team is aligned and self-coordinating behind the scenes.

Early Visibility Into Cost and Schedule

Because construction input is integrated into the design process, owners receive more accurate and earlier insight into project costs and timelines. Real-time cost modeling allows scope adjustments before drawings are finalized, while phasing strategies and manufacturing coordination can compress delivery schedules.

Fewer Disputes, Smoother Closeout

The design-build model reduces the adversarial dynamic that sometimes occurs in traditional delivery. With fewer parties and no handoffs between design and construction, the project experiences fewer disputes, change orders, or surprises. Closeout is more predictable, with a direct path for post-construction support or warranty follow-up.

In short, the owner’s experience in design-build is more collaborative, informed, and efficient. While active participation is still critical, the process is structured to reduce friction and provide greater confidence in project delivery.

How Design-Build Construction Benefits Developers

For developers, design-build isn’t just a delivery method — it’s a smarter way to reduce risk, accelerate timelines, and take control of project outcomes. By unifying design and construction under one contract, this model creates a more efficient, transparent, and collaborative process from day one.

1. Speed and Cost Efficiency

Design-build helps developers deliver projects faster, with better financial visibility and fewer delays.

- Faster project delivery through overlapping design and construction phases. At FINFROCK, our jobs are estimated to be completed 40-50% faster than traditional design-bid-build construction methods.

- Earlier knowledge of construction costs via integrated estimating and real-time cost modeling

- Reduced opportunity cost by generating revenue sooner through faster occupancy

- More predictable project costs with fewer surprises or late-stage redesigns

- Lower administrative burden thanks to simplified communication and fewer contracts

2. Reduced Risk and Greater Control

With one team accountable for the entire project, developers gain tighter control over cost, scope, and quality — while reducing legal exposure.

- Single point of contact for design, construction, and execution

- One contract simplifies legal structure and reduces coordination complexity

- Fewer change orders and disputes due to aligned priorities and proactive coordination

- Lower risk from clearer accountability and earlier issue detection

- Enhanced safety planning thanks to construction input during design

3. Stronger Collaboration and Flexibility

The integrated nature of design-build improves coordination across teams and enables better, faster decision-making.

- Improved communication and collaboration from day one

- Greater flexibility to adjust scope or systems during design without starting over

- Increased transparency and accountability across budgets, schedules, and milestones

- Active owner participation in key decisions without the need for daily oversight

4. Better Project Quality

By aligning teams early, design-build promotes better planning, cleaner execution, and consistent performance throughout the build.

- Improved quality assurance through continuous coordination, not reactive fixes

- Fewer construction errors and scope gaps due to unified documentation and communication

- Stronger execution from engineers, builders, and trades working in sync

- Smoother closeout with fewer punch items and cleaner handoffs

Are There Any Downsides to Design-Build?

While design-build offers clear advantages, it is not without its challenges. Developers considering this model should understand potential limitations and how to address them through proper team selection, project alignment, and contractual clarity.

Less Competitive Design Input

In traditional models, owners may solicit multiple design concepts before selecting a final direction. With design-build, the design is typically developed by one team from the outset. This can limit the ability to compare alternative concepts unless structured as a two-phase or design competition process.

How to address it:

Owners can build in design checkpoints or concept review phases, or use an RFQ-RFP process that includes preliminary design ideas from shortlisted firms.

Perceived Loss of Control

Some owners worry that giving one team control over both design and construction reduces their influence. However, in practice, design-build encourages more owner involvement at the right stages—particularly during early design development and scope definition.

How to address it:

Establish clear communication protocols and approval milestones within the contract to ensure transparency and collaboration.

Potential for Conflict of Interest

Because the same entity designs and builds the project, there is a concern that cost or schedule pressures could compromise design quality. While this is a risk, a reputable design-build team balances cost, performance, and aesthetics with long-term building value in mind.

How to address it:

Prioritize qualifications during procurement. Look for firms with a strong design culture, track record of architectural performance, and clear separation of roles within their integrated team.

Limited Legal Recourse

With a single contract, owners may feel they have fewer legal pathways if issues arise. However, this structure also reduces the likelihood of disputes between the architect and contractor—one of the most common sources of litigation in traditional delivery.

How to address it:

Ensure the contract includes detailed performance standards, warranties, dispute resolution procedures, and clear documentation protocols.

Not Always the Best Fit for Every Project

Design-build works best when the project benefits from early collaboration, fast-tracked delivery, or constructability-driven design. In projects where a fully developed design already exists, or where creative design competition is a priority, traditional models may be more appropriate.

How to address it:

Evaluate the project’s timing, scope, and goals before committing to a delivery model. Design-build is most effective when aligned with schedule-driven development and integrated decision-making from day one.

Design-build is not a one-size-fits-all solution. But when executed by a qualified team, with proper planning and oversight, its potential drawbacks can be effectively mitigated. The key is understanding the trade-offs and structuring the contract and team to protect project goals while capturing the model’s full benefits.

Design-Build vs Other Project Delivery Methods

Several project delivery methods are available, each with different levels of integration, risk, and control. Below is a brief comparison of how design-build stacks up against other common models.

Design-Bid-Build (DBB)

The owner hires a designer and, once design is complete, bids the project out to contractors. Coordination risks are higher, and timelines are often longer.

Read more: Design-Build vs Design-Bid-Build

Construction Management at Risk (CMAR)

A construction manager is engaged during design and later takes on construction risk through a GMP. Offers early input but maintains separate design and build contracts.

Integrated Project Delivery (IPD)

All parties share one contract, risk, and reward. Highly collaborative but requires significant alignment and legal coordination up front.

Comparison Table

| Model | Contract Structure | Cost Predictability | Speed | Risk to Owner | Best For |

| Design-Build | Single contract | High | Fast | Lower | Schedule-driven or complex coordination |

| Design-Bid-Build | Separate design + build | Medium to low | Slow | Higher | Public or fully designed projects |

| CMAR | Separate, with early input | Medium | Moderate | Moderate | Projects needing early contractor input |

| IPD | Multi-party agreement | High | Fast if aligned | Shared | High-collaboration, high-stakes builds |

When to Choose Design-Build

Design-build is best suited for projects that benefit from early collaboration, schedule acceleration, and integrated decision-making. While not ideal for every development, it offers distinct advantages when timing, coordination, and cost control are critical to success.

Design-build is often the right fit when:

- The project is in early stages

If land has been acquired but design is not yet finalized, the design-build team can guide feasibility, permitting, and phasing with construction in mind from day one. - Speed to market matters

The ability to overlap design and construction activities allows for faster delivery compared to sequential models. - The owner values cost certainty and fewer surprises

Continuous cost modeling throughout the process reduces the likelihood of overruns or major redesigns.

Constructability and logistics are central to success

Projects with tight sites, complex phasing, or manufacturing integration benefit from early construction input during design.

The team can be selected based on qualifications

Design-build works best when the owner chooses a team for their expertise, past performance, and integrated capabilities—not simply the lowest bid.

Design-Build May Not Be Ideal If:

- The design is already 80% complete and ready for bid

- Multiple competing design concepts are a priority

- Procurement rules require low-bid selection

Quick Evaluation Checklist

✅ Need to accelerate schedule without compromising quality

✅ Want a single contract and clear accountability

✅ Prefer early visibility into cost and constructability

✅ Plan to involve construction methods like precast or modular design

✅ Seeking fewer change orders and reduced administrative oversight

If you can check most of the boxes above, design-build is likely the right choice.

How to Select a Design-Build Contractor

Choosing the right design-build contractor is one of the most important decisions a developer will make. Since the selected team will manage every phase of the project—from concept to completion—selection should be based on qualifications, integration capabilities, and past performance rather than price alone.

What to Look For

- Proven track record with similar project types

Look for experience delivering projects of similar scale, use, and complexity under a design-build model. - In-house design and construction capabilities

A tightly integrated team provides greater control, faster decision-making, and smoother coordination. Ask whether key design and construction personnel are employed directly or subcontracted. - Collaborative project approach

A good design-build contractor fosters open communication, early problem-solving, and alignment around owner goals—not just design efficiency or cost. - Preconstruction planning expertise

Evaluate their ability to provide cost modeling, constructability reviews, phasing strategies, and schedule forecasting early in the design process. - Clear project controls and transparency

Ask how they manage budgets, changes, communication, and reporting. Look for open-book pricing models and real-time updates. - Quality assurance and safety systems

Review their quality control procedures, field supervision model, and safety record. - Strong references and repeat clients

A history of long-term relationships is often a better indicator of success than a polished proposal.

Questions to Ask During Interviews

- How do you handle design changes after construction has begun?

- Who will be my day-to-day point of contact?

- How do you coordinate between design, construction, and trade partners?

- What percentage of work is self-performed vs. subcontracted?

- How do you ensure pricing remains competitive during procurement?

- Can you provide examples of similar projects and how you managed schedule, cost, and risk?

Red Flags to Watch For

- Limited design-build experience or mostly traditional project history

- Rigid workflows with little room for owner input

- Lack of detail in preconstruction services or estimating

- Vague answers about team structure or roles

- Overemphasis on price rather than process, quality, or accountability

What Is a Typical Design-Build Contract?

A design-build contract consolidates responsibility for both design and construction into a single agreement between the owner and the design-build entity. While contract formats may vary depending on project size, delivery complexity, and legal requirements, most design-build contracts include the following core components:

Key Elements of a Design-Build Contract

| Component | What It Covers |

| Scope of Work | Defines design services, construction responsibilities, and performance standards |

| Design Services | Specifies deliverables, submittal phases, and owner approval points |

| Construction Services | Covers materials, labor, equipment, and coordination of subcontractors |

| Contract Price | Lump sum, cost-plus with GMP, or other agreed pricing model |

| Schedule | Includes project milestones, substantial completion dates, and delay provisions |

| Change Orders | Outlines procedures for scope changes and associated cost/time adjustments |

| Allowances & Contingencies | Defines how unknowns or flexible items are managed within the contract |

| Payment Terms | Details progress billing, retainage, and final payment procedures |

| Warranties | Sets performance periods and coverage for both materials and workmanship |

| Insurance & Bonding | Specifies minimum coverage and required bonds |

| Termination Clause | Covers default, convenience, and dispute resolution pathways |

| Dispute Resolution | Defines methods such as mediation, arbitration, or litigation |

Design-build contracts often include additional provisions related to collaboration, transparency, and performance tracking. Owners may also negotiate open-book cost structures, milestone-based incentives, or early project closeout bonuses.

Ultimately, the contract should reflect the integrated nature of the delivery model, provide clear accountability, and align incentives across design and construction teams.

Does Design-Build Include Competitive Bidding?

One of the most common misconceptions about design-build is that it eliminates competitive pricing. While it’s true that the owner is not bidding out construction documents to multiple general contractors, competition still exists—just at a different level.

In a design-build project, competitive bidding often takes place at the vendor and trade subcontractor level. Once the design reaches an appropriate level of development, the design-build team solicits multiple bids from qualified subcontractors and suppliers. This allows the owner to benefit from market-based pricing while maintaining the efficiency and accountability of a single-source delivery model.

Benefits of Vendor-Level Competition in Design-Build:

- Access to multiple bids per trade for better pricing

- Early involvement of trades improves accuracy and coordination

- Faster procurement through phased design and release packages

- Reduced change orders due to constructability-informed design

- Ability to prequalify vendors based on safety, quality, or past performance

Design-build doesn’t eliminate competition—it simply moves it to a point in the process where pricing can be more informed, strategic, and aligned with project priorities.

Hire FINFROCK for Your Next Project

If you’re exploring design-build as a project delivery method, partner with a firm built to deliver it at the highest level. At FINFROCK, we don’t just coordinate architecture, engineering, and construction—we own it, align it, and execute it with precision.

From the earliest feasibility study to final turnover, we act as a true extension of your team—bringing clarity, cost certainty, and speed to every stage of development. With decades of proven success in delivering complex structures through an integrated process, FINFROCK is uniquely positioned to help you realize your project’s full potential.

Ready to talk about your next development? Let’s start the conversation.