Setting the Stage: How to Think About Project Delivery

Your delivery method isn’t just a procedural choice—it’s a strategic one. It dictates how decisions are made, how teams interact, and how risks and responsibilities are distributed. In other words, it shapes both the process and the outcome.

Design-build and design-bid-build are two of the most widely used models, each with distinct advantages. But instead of asking which model is better overall, the more productive question is: Which model best supports the priorities of this project?

To answer that, start by grounding your evaluation in the realities of your development goals:

- What’s the most critical driver for this project—speed, cost, or design?

- Do we have internal capacity to manage multiple vendors?

- Is early cost certainty more important than extensive design input?

- Are we operating under time or budget constraints?

- Do we need to limit risk exposure?

- Does this project require complex system coordination?

These questions aren’t theoretical—they directly impact which delivery structure will work with you, not against you.

To bring these considerations into focus, the table below outlines how key factors compare across the design-build and design-bid-build models.

At-a-Glance Comparison Table

| Category | Design-Build | Design-Bid-Build |

| Contract Structure | Single contract between owner and design-builder | Separate contracts for designer and contractor |

| Project Timeline | Phases can overlap for faster delivery | Linear process often results in longer schedule |

| Cost Certainty | Budget informed early during design | Costs determined after design completion |

| Owner Involvement | Less day-to-day management required | Higher involvement and coordination needed |

| Risk Allocation | Shared risk among design-builder team | Owner assumes more risk between parties |

| Design Control | Integrated team may reduce owner’s control | Greater control over design and specifications |

| Change Orders | Fewer due to early coordination | More frequent, especially post-bid |

| Team Dynamics | Collaborative and aligned from the start | Potential for adversarial relationships |

| Best For | Fast-track projects, cost certainty, integration | Projects prioritizing design control or bidding |

What Is Design-Build?

Design-build is a project delivery method where the design and construction responsibilities are handled by a single, unified team under one contract. Instead of the owner coordinating between an architect and a general contractor, the design-builder manages both disciplines, creating a collaborative approach that streamlines decision-making, reduces risk, and accelerates the project timeline.

This integrated model is particularly effective for complex or time-sensitive projects where early cost clarity, tighter budget control, and ROI certainty are essential.

Key Advantages of Design-Build

1. Schedule Efficiency

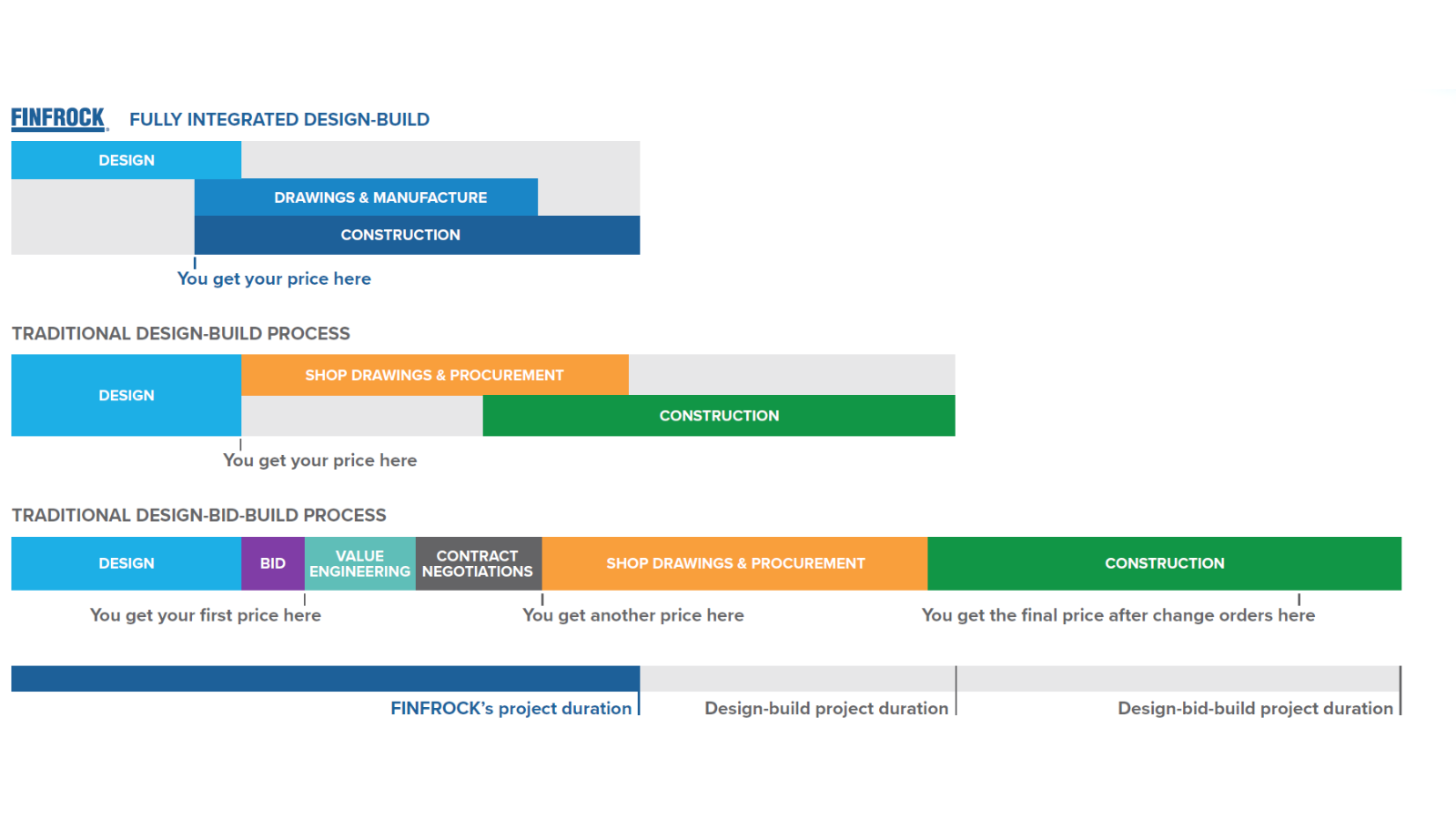

Design and construction phases can occur simultaneously, which allows work to begin before final design documents are completed. This overlapping schedule compresses the overall timeline, enabling faster project delivery and quicker market lock-in. Early constructibility input also minimizes rework and accelerates permitting and approvals, reducing the project’s overall opportunity cost.

2. Cost Certainty and Budget Control

With contractor insights integrated from the start, construction costs are considered during the design process. That leads to more predictable project costs, fewer budget surprises, and a significantly lower risk of change orders. This model also allows for real-time value engineering and sharper estimates, improving cost certainty and maximizing long-term ROI.

3. Simplified Communication and Accountability

Design-build gives owners a single point of contact and a single contract for the entire project, reducing the potential for miscommunication and siloed decision-making. The unified team structure improves collaboration, increases transparency, and ensures everyone is aligned on budget, scope, and schedule from day one. The result is better project management and more consistent accountability across phases.

4. Owner Convenience

Owners benefit from reduced management requirements and a lighter administrative load. Because the design-builder oversees coordination between trades and design disciplines, the owner is freed from day-to-day issue resolution. This reduces the administrative burden and gives developers more time to focus on higher-level priorities, ultimately saving both time and money.

5. Integrated Risk Mitigation

Shared goals and early alignment reduce miscommunication and legal disputes. Risk is not only lowered for the owner but also for the project team, thanks to tighter scopes, earlier identification of design conflicts, and fewer contractual handoffs. With reduced change orders and faster conflict resolution, design-build delivers lower overall project risk and smoother execution.

6. Best Fit for Complex or MEFP-Heavy Projects

Projects with intensive mechanical, electrical, fire protection, or structural systems benefit from early team integration. Design-build allows those technical disciplines to weigh in during design—ensuring feasibility, cost-efficiency, and system compatibility. For these MEFP-heavy projects, the result is improved quality assurance and fewer downstream issues.

Common Concerns with Design-Build—and How to Address Them

1. Perceived Loss of Control

Some owners worry that without a separate architect acting as an independent advocate, their influence over design decisions may diminish. There’s a perception that constructability or cost could override design intent, especially if roles and expectations aren’t clearly defined at the outset.

How to address it:

Owners should define project priorities early—whether design aesthetics, speed, budget, or long-term performance—and ensure they’re reflected in the contract. Including design charrettes, regular owner reviews, and defined approval stages can keep the owner actively engaged throughout the process.

2. Limited Competitive Bidding

Since the contractor is selected before design is complete, some owners feel they lose the ability to compare multiple GC bids. This can raise concerns about price transparency and value for money, particularly on cost-sensitive developments.

How to address it:

Owners can require open-book pricing, which provides visibility into subcontractor quotes, material costs, and markups. Competitive pricing still happens at the trade level. Using a qualifications-based selection process (RFQ + RFP) that evaluates both cost strategy and delivery approach ensures a balanced decision.

3. Early Commitment Before Full Design

Design-build typically begins with a partnership based on conceptual design, which can feel risky to owners accustomed to signing contracts after reviewing detailed construction documents. This may raise concerns about flexibility and control later in the process.

How to address it:

To manage this, owners can use a phased design-build agreement, starting with a preconstruction services contract and committing to full execution once design reaches a defined milestone. This structure allows time to validate the budget, design direction, and team performance before full authorization.

4. Risk of Team Misalignment

If the design-builder’s internal or partnered teams are mismatched in skill or communication, it can lead to inconsistent quality, coordination issues, or construction delays.

How to address it:

Strong team vetting is critical. Owners should evaluate the design-builder’s past project history, team bios, subcontractor network, and internal collaboration methods. Requesting to meet the proposed team—not just company leadership—during the selection process helps verify alignment in capabilities and communication.

What Owners Get Wrong About Design-Build

Despite its growing adoption across private and public sectors, design-build is still misunderstood by many owners and developers. While it offers clear benefits in speed, cost certainty, and collaboration, misconceptions often lead decision-makers to default to more familiar, but sometimes less efficient, delivery methods.

Here are some of the most common myths about design-build, and the truth behind them:

Myth 1: “Design-Build Means Giving Up Control”

Reality: Owners maintain control by clearly defining project goals, budgets, and priorities upfront. In well-structured design-build models, especially vertically integrated ones like FINFROCK’s, the owner works directly with one accountable partner, not a black box. You still approve the design, influence product choices, and review milestones; you simply don’t have to coordinate multiple contracts to do so.

Myth 2: “You Can’t Get the Best Price Without Competitive Bidding”

Reality: Traditional bidding often leads to the lowest bid not the best value. Design-build promotes cost visibility earlier in the process and allows the team to optimize solutions in real-time. By involving the builder during design, you reduce scope gaps, eliminate guesswork, and significantly lower the risk of change orders that inflate the final cost.

Myth 3: “It’s Too Risky to Try Something New”

Reality: Design-build isn’t new, it’s a proven delivery method used on billions of dollars’ worth of projects annually. When executed with a qualified team, design-build actually reduces risk by aligning design and construction from the start. Owners avoid the adversarial dynamics common in fragmented models and benefit from faster conflict resolution and clearer accountability.

Myth 4: “Design-Build Cuts Corners on Design Quality”

Reality: High-quality design is still achievable, and often enhanced in design-build projects. When design teams collaborate with construction teams early, the result is more constructible, cost-efficient solutions that still meet the owner’s vision. Integrated design doesn’t mean compromised design, it means smarter, better-informed decisions.

Myth 5: “Design-Build Is Only for Simple or Repetitive Projects”

Reality: Design-build has proven advantages on complex, MEFP-heavy projects, including hospitals, multifamily developments, hotels, and precast parking structures. In fact, the more integrated the systems, the more design-build can help improve coordination, reduce rework, and maintain schedule integrity.

What Is Design-Bid-Build?

Design-bid-build (DBB) is the traditional project delivery method in which the owner first hires a designer to create detailed plans and then separately contracts with a builder through a competitive bidding process. The project moves in a linear sequence: design is completed before bidding begins, and construction doesn’t start until after a contractor is selected.

This model offers a high level of owner involvement and is often preferred when design control, detailed documentation, and competitive bidding are key priorities.

Key Advantages of Design-Bid-Build

1. Full Owner Control

Design-bid-build gives owners direct control throughout the process. You select the architect, approve all design documents, and choose your contractor through a separate, transparent process. This separation reinforces design independence and ensures that the final outcome reflects the owner’s specific vision and requirements.

2. Familiarity and Clear Role Separation

As the most commonly used delivery model, DBB is familiar to many public and private owners. Roles are well-defined: the architect designs, the contractor builds, and the owner manages both parties. This role separation helps create predictable workflows and a straightforward scheduling path, especially for teams accustomed to this process.

3. Competitive Bidding and Price Transparency

Once the design is complete, multiple contractors can bid on the project based on the same set of plans. This allows owners to price shop, compare proposals, and select the lowest qualified bidder. It also gives access to a large pool of contractors, especially beneficial in markets where availability is high.

4. Objective Design Development

Because the builder is not involved during design, the architect can focus fully on the owner’s needs without pressure to reduce scope for construction ease. This results in objective design decisions and detailed documentation, which can be valuable for complex architectural features or highly customized projects.

Common Drawbacks of Design-Bid-Build

1. Longer Timelines

Because design, bidding, and construction happen sequentially, DBB typically leads to longer project timelines. If bids come in over budget, it may trigger redesigns and additional approvals, extending timelines and increasing soft costs. This process also offers no room for quick decision-making once documents are finalized.

2. Budget Uncertainty and Cost Risk

Since construction costs are determined later in the process, owners often proceed through design without a firm sense of what the project will actually cost. This creates a greater risk of cost overruns, particularly on complex or fast-paced projects. If budget gaps emerge post-bid, change orders become more frequent and expensive.

3. Fragmented Communication

Designers and contractors work independently, and the owner must act as the go-between. This increases the administrative burden and opens the door to communication gaps. Without builder input during design, potential issues may go unnoticed until construction begins, leading to RFIs, scope changes, and disputes.

4. Higher Project Risk and Disputes

With separate contracts and siloed teams, there’s a higher likelihood of team conflicts and adversarial relationships. If problems arise, contractors may point to design flaws while architects blame construction execution, leaving the owner in the middle. DBB also places more project risk on the owner, who must manage coordination and liability between parties.

5. Rigid Process and Market Vulnerability

The linear process can be rigid once construction begins, leaving little flexibility to accommodate changes or new product considerations. Without contractor involvement during design, things like material availability, labor costs, or equipment pricing may be overlooked. In hot markets, where demand outpaces supply, owners may face fewer bids, higher prices, and less qualified contractors, further increasing cost exposure.

FAQ: Quick Answers

What’s the difference between design-build and design-bid-build?

Design-build uses a single contract for both design and construction, with one integrated team. Design-bid-build separates design and construction into two contracts, with the owner managing coordination between the architect and contractor.

Which method delivers faster project timelines?

Design-build generally enables faster delivery because the design and construction phases can overlap. Design-bid-build follows a linear process, which typically results in longer timelines.

Does design-build offer better cost control?

Yes. Design-build allows for earlier cost integration, fewer change orders, and more predictable project costs. Owners gain pricing visibility much sooner than in design-bid-build, where construction costs are only known after bidding.

Will I lose design control in a design-build model?

Not necessarily. While the builder and designer work as one team, owners still approve key design decisions. With a qualified design-build partner, you can set expectations upfront and retain meaningful input throughout the process.

Is design-bid-build better for competitive pricing?

Design-bid-build promotes competitive pricing by allowing contractors to bid on the same design documents. However, this can also lead to low bids that overlook complexity—potentially increasing risk for cost overruns and disputes.

Which method is better for complex projects?

Design-build is typically better suited for complex or MEFP-heavy projects. Early coordination between disciplines helps reduce rework, improve constructibility, and manage technical risks more effectively.

The Future of Project Delivery

As the construction industry evolves, project delivery methods are adapting to meet new demands—faster timelines, tighter budgets, greater technical complexity, and shifting labor availability. Both design-build and design-bid-build will continue to play roles in future projects, but design-build is rapidly gaining momentum.

Design-Build Adoption Is Growing

According to the Design-Build Institute of America (DBIA), design-build now accounts for over 44% of construction spending across the U.S., a share that continues to grow. Private developers and public agencies alike are embracing the model for its proven ability to maximize cost savings, compress schedules, and improve project outcomes.

This growth is particularly strong in:

- Healthcare

- Transportation and infrastructure

- Multifamily and hospitality

- Education

- Large-scale commercial and industrial projects

Case in Point: RCID Parking Complex at Disney Springs

One of the clearest examples of design-build success in a complex, high-traffic environment is the RCID Parking Complex—better known as the Grapefruit Garage—at Disney Springs in Lake Buena Vista, Florida.

Tasked with adding over 3,000 parking stalls to one of the nation’s busiest entertainment destinations, FINFROCK delivered the structure as architect, engineer of record, manufacturer, and contractor—all under one design-build contract. This integrated model allowed for precise coordination with existing infrastructure, adherence to strict aesthetic guidelines, and the addition of key features such as:

- A pedestrian bridge connection

- Speed ramps for improved traffic flow

- A parking guidance system for real-time space tracking

By combining architecture, engineering, manufacturing, and construction within a single delivery team, the project avoided costly delays and design conflicts—delivering a high-capacity garage on time and in full alignment with Reedy Creek Improvement District’s operational and visual standards.

This project showcases how design-build is not only shaping the future—it’s already delivering it.

Technology Is Expanding Design-Build’s Capabilities

Technology like Building Information Modeling (BIM) and Virtual Design & Construction (VDC) are enhancing coordination between teams, improving design accuracy, and reducing field errors. These platforms support real-time collaboration between design and construction professionals, making them especially compatible with the integrated structure of design-build delivery.

In models where fabrication is integrated (like FINFROCK’s), digital tools can also connect directly to manufacturing workflows, reducing waste and accelerating production.

Legislative Changes Are Opening New Opportunities

Several states that once restricted the use of design-build, especially for public projects, are now revising procurement laws to allow or even favor integrated delivery. As owners continue to seek higher value and reduced risk, legislation is increasingly catching up to the benefits of design-build.

However, project type and funding source still impact what’s legally allowed. Public institutions and municipalities may still be required to use design-bid-build unless state-level reforms are in place.

Emerging Models: Progressive Design-Build & Hybrid Approaches

The industry is also seeing growth in progressive design-build, where a team is selected based on qualifications before pricing is finalized. This allows early collaboration and scope definition while maintaining flexibility. Similarly, some firms are experimenting with hybrid models that combine the best aspects of DB and DBB for specific project needs.

As delivery methods evolve, the core trend is clear: owners are looking for smarter, faster, and more reliable ways to build, with design-build leading the shift.

How FINFROCK Elevates Design-Build

While design-build offers significant advantages over traditional delivery methods, it’s not without its challenges especially when it comes to design control, accountability, and team alignment. FINFROCK addresses these challenges through a vertically integrated model that brings architecture, engineering, manufacturing, and construction together under one roof.

This unified approach transforms design-build from a process into a product, delivering unmatched schedule certainty, cost predictability, and project performance.

1. Full Vertical Integration = Total Accountability

At FINFROCK, we don’t just manage the design-build team, we are the team. Our in-house professionals handle every phase, from conceptual design to precast manufacturing to final construction. This eliminates the disconnect between designer and builder, while providing a single point of accountability throughout the entire project lifecycle.

2. Greater Owner Control Through Alignment

Unlike traditional design-build teams where the designer and builder are paired externally, our integrated team works collaboratively from day one the owner’s goals clearly prioritized. You maintain real design influence, while gaining the benefits of coordinated engineering and early constructibility review. We bridge the gap between design vision and execution without sacrificing either.

3. Early, Accurate Pricing with Fewer Surprises

Because our construction and manufacturing experts are involved in early-stage design, we deliver earlier cost certainty with pricing that reflects real-world production and labor conditions. This leads to more predictable project costs, reduced change orders, and higher ROI certainty from start to finish.

4. Precision Manufacturing for Speed, Quality, and Safety

FINFROCK’s proprietary precast concrete systems are manufactured in a controlled environment, allowing for faster assembly on-site, superior quality assurance, and reduced safety risks. By integrating design, detailing, and fabrication, we compress schedules and eliminate the delays common to conventional construction.

5. Fewer Risks. Better Outcomes.

Our delivery model removes many of the traditional risks that come with either design-build or design-bid-build such as scope gaps, low-bid compromises, or adversarial team relationships. With FINFROCK, owners don’t have to choose between control and speed, or design quality and budget discipline. We deliver all of it, efficiently, transparently, and with proven results.

Real-World Results: Lake House Apartments

The Lake House Apartments in Orlando’s Ivanhoe Village highlight how FINFROCK’s integrated model delivers high design quality without sacrificing speed or cost control.

Serving as design-builder, architect, structural engineer, and precast manufacturer, FINFROCK worked closely with neighborhood groups to honor the area’s historic character while delivering a standout luxury property.

Key outcomes included:

- Full Vertical Integration: Our in-house team managed all design, manufacturing, and construction, allowing us to align design intent with buildability from day one.

- Owner Control Through Alignment: Design input from multiple neighborhood groups was respected and incorporated without compromising schedule or cost—thanks to tightly integrated design coordination.

- Early, Accurate Pricing: Real-time collaboration between design and construction teams enabled early cost clarity, reducing surprises and controlling budget drift.

- Precision Manufacturing: The use of our DualDeck® Building System and advanced BIM modeling enabled faster construction, higher-quality finishes, and reduced risk during delivery.

The result: a 9-story, 252-unit mixed-use building with over 500 structured parking spaces—delivered efficiently, transparently, and with complete alignment between design intent and execution.

Why Design-Build with FINFROCK Is the Smarter Choice

Choosing the right project delivery method has a direct impact on your schedule, budget, and level of risk. While design-bid-build remains familiar to many, it often creates fragmented communication, delayed timelines, and higher administrative demands on owners.

Design-build simplifies the process, but FINFROCK takes it further. Our vertically integrated design-build approach combines architecture, engineering, precast manufacturing, and construction into one seamless team. This means fewer change orders, earlier cost certainty, and faster delivery without sacrificing control or quality.

If you’re planning a project that demands precision, speed, and predictable ROI, FINFROCK’s model is built for it. Let’s build it better together.