Modular construction is a building process that shifts core activities—like framing, mechanical fit-out, and interior finishing—from traditional job sites into highly controlled factory environments. Unlike conventional construction, where every structure is built as a one-off project, modular construction transforms buildings into repeatable systems assembled from prefabricated components or fully finished volumetric modules.

This shift toward modular design in construction represents more than just an operational change, it’s a strategic evolution. By industrializing the construction process, developers gain tighter cost control, faster schedules, and more consistent quality. It’s why modular is increasingly viewed not just as an alternative, but as the future of construction.

At its core, modular design construction leverages prefabrication—a broader concept that includes everything from wall panels to service pods to complete room-sized modules. While prefabrication has long played a supporting role in traditional builds, modular construction takes it further by centralizing production, reducing reliance on field labor, and enabling parallel scheduling between site and factory.

The numbers speak for themselves. According to the Modular Building Institute, modular construction can shorten overall project timelines by 30–50% and reduce material waste, site disturbance, and environmental impact. As labor constraints grow and developers face tighter pro formas, these efficiencies offer a powerful advantage.

While modular isn’t a new concept, its role in architecture and real estate has changed significantly over the decades. Early use cases spiked after World War II to address urgent housing shortages, but design limitations and quality concerns stunted long-term adoption. Today, advancements in digital modeling, manufacturing, and materials have redefined what’s possible. Modular building design now competes in sectors once considered out of reach—including multifamily, healthcare, education, and high-end hospitality.

In short, modular construction is no longer about temporary solutions or boxy aesthetics. It’s about rethinking the building process—from the ground up—as something that can be optimized, repeated, and scaled for long-term value.

Adopting a Modular Mindset

Succeeding with modular construction starts by shifting your perspective. Instead of treating each project as a custom build, modular rewards a product-based approach—one where repeatable units are configured, not reinvented.

This means thinking like a manufacturer. Efficiency comes from standardization, early coordination, and a streamlined process that prioritizes how buildings are built, not just how they look.

Modular also changes the timeline. Key decisions must be made early, and partners brought in at the start—not after design is complete. Waiting too long reduces the very advantages modular offers.

Every project sits on a sliding scale of cost, quality, labor, and risk. Modular helps rebalance that—but only when teams plan for it from the beginning, with the right people in place. Teams with modular experience and repeatable workflows perform better, faster, and more predictably.

Modular isn’t a plug-in solution. It’s a mindset shift—from managing projects to managing products.

Key Aspects of Modular Construction

Modular construction is defined by a set of principles that differentiate it from traditional methods:

- Off-site Fabrication

Modules are built in a factory setting rather than on-site, allowing for better quality control, faster production, and reduced weather delays. - Standardized Components

Modular systems are designed around repeatable units framed to precise specs for transport, stacking, and efficient installation. - Controlled Environment

Construction takes place indoors, where materials stay dry and crews follow consistent workflows. Modules are typically built inside-out, starting with plumbing, electrical, and finishes before exterior cladding—opposite of how buildings are assembled in the field. - On-site Assembly Considerations

Modules are delivered as complete units and craned into place. Pick points for lifting must be engineered into the design, along with planning for access, staging, and alignment with the building’s structural system.

These aspects make modular construction not just faster—but more predictable, more repeatable, and often higher quality than traditional site-built methods.

The Modular Construction Process

Modular construction replaces the fragmented sequence of traditional building with a streamlined, parallel workflow—moving design, manufacturing, and site work forward simultaneously. Below is an overview of each major phase, from concept to completion.

Design for Modularity

Success begins with designing for the modular format from day one—not retrofitting a traditional plan. Architects and engineers develop unit layouts, structural systems, and connection details that align with manufacturing and craning constraints. Early decisions must account for transportation limits, pick points, interior sequencing, and local code approvals. Modular isn’t just a delivery method—it’s a design logic.

Off-Site Manufacturing

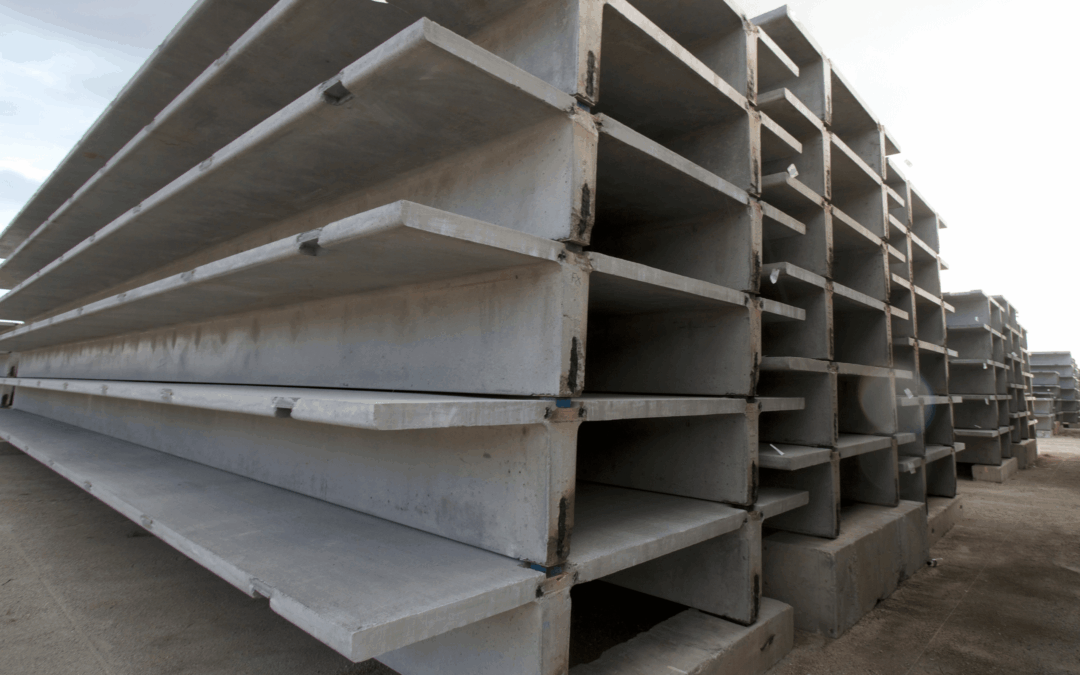

Modules are built in a controlled factory environment using a repeatable, assembly-style process. Work may include framing, MEP installation, insulation, drywall, painting, and fixture mounting—all to near-complete interior finish. This phase ensures consistent quality, tighter tolerances, and protection from weather delays. In concrete modular construction, components are precast, cured, and staged for delivery with durable precision.

Parallel Site Work

While modules are fabricated off-site, foundations and utilities are simultaneously prepared on-site. This overlap—called concurrent or parallel construction—breaks from the traditional linear critical path and is one of the biggest drivers of modular speed. Site readiness is tightly choreographed to align with module delivery and stacking.

Transport and Delivery

Completed modules are shipped via flatbed trucks or carriers, reinforced to withstand lifting, wind, and road stress. Route planning, weight limits, and DOT regulations shape module dimensions—typically maxing out at around 12–15 feet wide and 60 feet long. Proximity to the manufacturing facility plays a key role in cost-effectiveness and logistics feasibility.

On-Site Assembly and Finishing

Once delivered, modules are craned into place, stacked, and locked into the building’s permanent structure. Crews connect MEP systems, seal joints, and complete any exterior finishes or rooflines not handled at the plant. Interior touch-ups, inspections, and commissioning follow. When designed properly, stacking can be completed in days, not months—especially for repetitive floor plates.

The Difference Between Prefabricated and Modular Construction

While the terms are often used interchangeably, prefabrication and modular construction aren’t the same.

Prefabrication refers to any building element made off-site—like wall panels, floor systems, or bathroom pods—that’s later installed on-site. It supports traditional construction but doesn’t change the overall delivery model.

Modular construction, on the other hand, is a complete building strategy. It involves assembling full volumetric units—like apartment modules or hotel rooms—in a factory, then stacking and connecting them on-site to create the entire structure.

Example: A precast stair core is prefabricated. A fully finished hotel room, complete with plumbing, lighting, and finishes, is modular.

Modular includes prefabrication—but takes it further, turning construction into a repeatable, scalable system.

Types of Modular Construction

Modular construction isn’t one-size-fits-all. Several approaches exist, each suited to different project needs:

- Permanent Modular Construction (PMC)

Designed for long-term use and built to the same codes as site-built structures. Ideal for multifamily, healthcare, hospitality, and education projects. - Relocatable Modular Buildings

Temporary or semi-permanent structures that can be moved and reused. Common in site offices, classrooms, and emergency housing. - Volumetric Modules (3D)

Complete, room-sized units built off-site with walls, floors, ceilings, and interior finishes. These modules are stacked or arranged to form the full building. - Panelized Systems (2D)

Flat assemblies—like walls, floors, or roof panels—transported separately and assembled on-site. Offers more design flexibility but requires more field labor. - Hybrid Modular Construction

Combines 2D panels and 3D volumetric modules within the same project. For example, using bathroom pods (3D) with panelized walls (2D) and site-built public areas.

Success doesn’t come from choosing one type—**it often comes from optimizing the right mix of 2D, 3D, and hybrid solutions based on project complexity, site logistics, and manufacturing constraints.

Where Can Modular Construction Be Applied?

Modular construction is most effective where demand is high, labor is limited, and repeatability drives value. It thrives in urban infill projects with tight access, remote areas with high labor costs, and regions with short construction seasons where weather delays are common.

Feasibility improves when projects are located within reasonable proximity to a manufacturing facility, helping reduce transportation costs and complexity. Markets that combine housing demand with skilled labor shortages—including many parts of the U.S.—are especially well positioned for modular. Public-sector projects with standardized layouts, such as schools and affordable housing, are also strong candidates.

Common applications include:

- Residential – Especially mid-rise multifamily and modular apartment buildings.

- Commercial – Offices, retail complexes, and mixed-use developments.

- Healthcare – Clinics, urgent care, and patient rooms with standardized configurations.

- Office – Modular cores, flexible layouts, and temporary structures.

- Multifamily – One of the strongest fits due to high unit repetition and schedule sensitivity.

- Student Housing – Standardized room layouts and phased delivery make modular ideal.

- Hospitality – Hotels benefit from factory-built room modules with predictable quality and finish.

- Parking – Modular parking structures can be rapidly deployed, with reduced site impact and built-in expansion potential.

Advantages of Modular Construction

- Faster Construction – Off-site and on-site work happen in parallel, reducing overall timelines by 20–50% when teams are aligned.

- No Weather Delays – Factory production eliminates weather-related stoppages common in traditional builds.

- Concurrent Scheduling – Modular breaks from Critical Path sequencing by allowing simultaneous site prep and module fabrication.

- Cost Efficiency – Bulk procurement and streamlined labor coordination can yield up to 20% savings.

- Quality Control – Factory settings support repeatable, consistent construction with fewer on-site errors.

- Sustainability – Modular reduces material waste and boosts energy efficiency through tighter resource management.

- Lower Emissions – Fewer commutes and consolidated deliveries cut carbon output compared to traditional methods.

- Durability – Prefabricated concrete modules are manufactured with high precision and consistent reinforcement, producing structures that are often stronger, more resilient, and longer-lasting than conventionally poured or framed buildings.

- Adaptability & Flexibility – Modular layouts can be expanded or reconfigured to meet changing program needs.

- Repeatable Quality – Standardized manufacturing delivers uniform quality across units and projects.

- Improved Safety – Fewer trades on-site reduce crowding and lower the risk of jobsite incidents.

- Technology Integration – BIM and digital coordination tools support early design validation and cost modeling.

- Less Site Disruption – Shorter build times and fewer deliveries reduce neighborhood traffic and impact.

- Recyclable Components – Modules and materials can be disassembled and reused, extending asset life and reducing waste.

Challenges of Modular Construction

- Initial Design Complexity – Modular requires early design freeze and detailed coordination up front, making it critical to design for modular from day one—not retrofit traditional plans.

- Reduced Design Flexibility – Late-stage changes are costly; success depends on fast decision-making and tight order timelines to maintain cost control.

- Transportation Logistics – Module dimensions are limited by transport regulations, and structural reinforcement is often needed to withstand over-the-road movement.

- Shipping Distance Limits – While flexible, modular is generally more cost-effective when manufacturing and site locations are within a reasonable geographic range.

- Site Preparation – Setting modules requires precise foundation alignment, staging access, and crane coordination—minor delays can ripple through the schedule.

- Code Compliance – Modular permitting varies widely by jurisdiction, and unfamiliarity can lead to slower reviews or added inspection steps.

- Regulatory Resistance – In some markets, outdated building codes or lack of off-site permitting pathways can create friction for modular delivery.

- Factory-Level Approvals – Jurisdictions that allow factory-based plan reviews and inspections can greatly streamline modular projects—but early outreach is essential to confirm what’s possible.

These challenges are real—but all of them can be resolved with early planning, the right delivery model, and a team experienced in modular design and execution.

Myths About Modular Construction

Myth: Modular Buildings Are Low Quality or Unattractive

Factory-built modules are constructed in controlled environments with precise detailing and consistent finishes. As material options and design tools have evolved, modular buildings now deliver the same (or better) visual appeal and durability as traditional structures.

Myth: Modular Limits Design Freedom

Modular construction follows manufacturing logic—but that doesn’t mean it’s rigid. Hybrid and panelized systems offer design flexibility, allowing for varied layouts, custom facades, and architectural creativity within a modular framework.

Myth: Prefab Equals Cheap or Temporary

Prefabrication is no longer limited to jobsite trailers or temporary classrooms. Many modern modular projects are built with prefabricated concrete and permanent structural systems designed to meet or exceed local building codes.

The Reality: Perceptions Are Changing

Developers and end-users are increasingly viewing modular as a premium approach—not just for speed, but for its quality, sustainability, and long-term performance. The outdated associations with “cheap prefab” are giving way to a new standard: efficient, durable, and design-forward buildings.

Case Studies: Examples of Modular Construction

Real-world projects show how modular construction can solve complex challenges while delivering measurable value in speed, cost control, and site efficiency.

MAA Robinson

In downtown Orlando, Mid-America Apartment Communities (MAA) partnered with FINFROCK to develop a high-density, mixed-use project on a constrained site. The 11-story building includes 369 apartment units, a 725-stall parking garage, and nearly 4,000 square feet of restaurant space. A key complexity involved preserving 200 garage spaces for a previous property owner, requiring a carefully integrated design solution. FINFROCK served as architect, engineer, precast modular manufacturer, and general contractor—delivering a design-build approach that met MAA’s financial and operational needs. Despite launching during the height of the COVID-19 pandemic, the modular construction method kept the project on schedule, outperforming neighboring mixed-use developments and remaining on track for early turnover.

Harrah’s Pompano Beach Garage

At Harrah’s Pompano Beach, the challenge was maintaining casino operations on an active site while building structured parking that would support future phases of redevelopment. FINFROCK delivered a fully integrated solution, designing the garage to align with the rebranded casino and set the tone for the broader entertainment district, “The Pomp.” To satisfy a rooftop shading requirement, FINFROCK proposed a 32,000-square-foot solar array—turning a code constraint into a long-term energy asset with a payback period of under two years. The structural portion of the garage was completed in just over four months, showcasing how modular construction reduces labor costs and minimizes disruption in high-traffic, high-stakes environments.

These projects demonstrate how modular construction, when paired with integrated design and delivery, can solve complex site constraints, accelerate timelines, and create long-term value for developers.

Modular Construction vs. Traditional Construction

Modular and traditional construction methods differ in more than just where the building gets assembled—they represent two fundamentally different delivery models. Below is a comparison of key factors that impact cost, schedule, coordination, and long-term outcomes:

|

Factor |

Modular Construction |

Traditional Construction |

|

Speed |

Off-site fabrication and on-site work happen in parallel, reducing total build time. |

Sequential trade work extends timelines, with weather and labor delays common. |

|

Labor & Safety |

Fewer trades on-site and less time in the field reduces safety risks. |

Crowded job sites with overlapping trades increase exposure to accidents. |

|

Coordination |

Single team often manages design, fabrication, and construction under one contract. |

Multiple subcontractors require extensive coordination and change order management. |

|

Cost Certainty |

Early design freeze and integrated delivery allow for predictable pricing. |

Cost escalations are common due to late design changes and bid variability. |

|

Sustainability |

Factory-controlled waste reduction, lower emissions, and reusable components. |

Greater material waste, more deliveries, and less energy-efficient workflows. |

|

Site Logistics |

Fewer deliveries, shorter project duration, and reduced neighborhood disruption. |

Continuous deliveries, site congestion, and longer public impact windows. |

Modular construction doesn’t just change how buildings go together—it disrupts the fragmented subcontractor model, shifting control to a smaller, integrated team. This allows for more aligned decision-making, fewer handoffs, and a more reliable path from concept to completion.

When to Use Modular Construction

Modular construction isn’t a one-size-fits-all solution—it’s most effective when project conditions, timelines, and team structure align with its strengths. The following scenarios represent ideal use cases:

- At project conception or schematic design phase

Modular strategies work best when integrated early—before key layout and system decisions are locked in. - For fast-track projects with hard deadlines

Modular delivery enables concurrent factory and site work, reducing overall schedule duration. - For high-volume, repetitive typologies

Apartments, hotels, student housing, and parking garages benefit most from repeatable layouts and systems. - When a “product core” can be identified across projects

Standardizing unit types, corridors, or MEP assemblies across a portfolio unlocks scalability and manufacturing efficiency. - When teams are experienced and repeatable

Success increases when design, construction, and manufacturing teams work together across multiple modular projects. - When design can be tailored to manufacturing constraints

Projects designed specifically for factory production yield better results than retrofitted plans. - When supply chain coordination is prioritized

Strong vendor relationships and early procurement strategies are key to delivering modules on time and within budget.

Modular + Design-Build: Why Integration Matters

Modular construction performs best when it’s paired with a delivery model that supports it. That’s why design-build—and especially FINFROCK’s vertically integrated approach—is such a natural fit.

In traditional design-bid-build contracts, modular delivery often breaks down. Architects, engineers, contractors, and manufacturers are hired separately, leading to fragmented accountability and late-stage decisions that conflict with manufacturing logic. Design changes after procurement, poor coordination, and unclear ownership of scheduling or logistics can erode the very benefits modular is meant to deliver.

By contrast, design-build brings every discipline under one roof—from design to engineering to manufacturing and construction. This integration is essential for modular success, where early decisions, shared goals, and continuous coordination are non-negotiable.

FINFROCK’s model goes even further. As architect of record, engineer of record, precast manufacturer, and general contractor, we eliminate the handoffs that slow down other teams. Our patented DualDeck® system—a modular precast floor and ceiling assembly—is just one example of how we combine structure, efficiency, and finish quality into a single, repeatable building component.

As prefab and off-site construction gain ground, traditional contractors who rely on managing trades in the field are increasingly being cut out of the value chain. The future favors builders who can align design, manufacturing, and delivery—and that’s exactly where modular and design-build converge.

The Growth of Modular Design Into the Future

As pressure builds to deliver smarter, faster, and more affordable buildings, modular construction is emerging as a transformative force across the industry. It plays a key role in addressing urgent housing shortages by enabling faster delivery of multifamily units, especially in markets struggling to keep pace with demand. At the same time, factory-based workflows help ease the impact of skilled labor shortages by reducing reliance on traditional on-site trades.

Modular is also proving ideal for urban infill and constrained sites where conventional construction would face delays, safety issues, or cost overruns. The market reflects this shift: modular construction is projected to generate over $130 billion in annual value across the U.S. and Europe by 2030, according to McKinsey. Much of this growth is being driven by digitization—tools like BIM, automated design systems, and integrated manufacturing are making modular delivery more efficient and scalable than ever.

Public policy is accelerating the trend. Government incentives, updated codes, and public-sector investments in schools, housing, and healthcare facilities are helping to normalize modular delivery as a future-ready standard. Together, these forces are positioning modular not just as an alternative—but as a foundational solution for what comes next.

Frequently Asked Questions

How are modular buildings constructed?

Modular buildings are assembled from factory-built components—typically panels or 3D volumetric modules—which are delivered to the site and installed using cranes. Site work, such as foundations and utilities, often happens concurrently to shorten the timeline.

Is modular construction cheaper?

Modular construction can be up to 20% more cost-efficient when executed at scale with aligned teams. However, cost savings depend on early planning, efficient logistics, and minimizing design changes.

Is modular construction sustainable?

Yes. Modular significantly reduces material waste, streamlines energy use, and limits carbon emissions by consolidating deliveries and reducing jobsite commutes.

How many construction workers are needed for modular buildings?

Fewer than traditional methods. Much of the labor shifts to the factory, which requires smaller, specialized teams. On-site crews are needed mainly for setting and final assembly.

What are the components of modular construction?

Typical components include floor systems, walls, ceilings, mechanical/electrical/plumbing (MEP) systems, and finishes—either in 2D panelized or fully finished 3D volumetric formats.

Does modular construction allow for tighter cost containment?

Yes. Early design freeze, repeatable components, and integrated procurement help control costs and reduce unexpected budget changes.

Does modular construction save you money on construction costs?

It can. Savings come from reduced labor, faster timelines, and less waste—but only when the project is designed specifically for modular delivery from the outset.

How does modular construction impact the environment?

Modular reduces emissions by requiring fewer deliveries and enabling denser, more efficient transport. It also minimizes jobsite disturbance and resource consumption.

How is modular construction sustainable?

Sustainability stems from material efficiency, energy savings, and reduced on-site impact. Modules can also be repurposed or recycled, extending their lifecycle.

How much does modular construction reduce pollution?

By cutting down on jobsite traffic, minimizing waste, and reducing long-distance commutes, modular construction can lower construction-related emissions by a measurable margin.

A Smarter Modular Partner: Why Developers Choose FINFROCK

Choosing the right partner is what makes modular work.

FINFROCK delivers modular construction as a complete, end-to-end solution—combining design, engineering, manufacturing, and construction within a single, integrated team. Our proprietary DualDeck® system and vertically integrated model unlock faster delivery, tighter cost control, and reduced risk across multifamily, mixed-use, and commercial developments. For developers ready to build smarter, FINFROCK makes modular possible.